Guide to Using a Plastic Welding Kit for Efficient Repairs

By:Admin

*[Company Name]*, a leading manufacturer in the field of plastic repair solutions, is set to redefine the industry with its latest innovation—the Plastic Welding Kit. This advanced tool offers a reliable and efficient method for repairing, joining, and reinforcing various plastic materials, providing a cost-effective and sustainable solution.

Plastic is one of the most versatile materials used in various industries, from automotive to construction and even household items. However, when damaged, plastic components often require replacement, leading to increased costs and generating unnecessary waste. The Plastic Welding Kit aims to address this issue by enabling users to repair damaged parts, prolonging their lifespan and reducing the environmental footprint.

The Plastic Welding Kit consists of a robust handheld welding unit, an assortment of specialized plastic welding rods, and a set of accessories for optimal repair performance. The welding unit features a temperature control system, allowing users to precisely apply heat to the damaged plastic, ensuring proper melting and fusion. This ensures a strong and durable bond, similar to the original material.

The versatility of the Plastic Welding Kit is unmatched, as it can weld various types of plastic, including ABS, PVC, polycarbonate, polypropylene, and many more. With the ability to repair a wide range of plastics, this kit serves as an essential tool for professionals in industries such as automotive repair, manufacturing, and even DIY enthusiasts.

The key benefit of this innovative kit lies in its ease of use. Even novices can quickly grasp its operation, thanks to the comprehensive user manual provided by *[Company Name]*. Following simple steps, users can repair cracks, holes, and tears in plastic components with precision and efficiency. By adopting the Plastic Welding Kit, industries can save time and money by avoiding costly replacements.

Moreover, by using the Plastic Welding Kit, companies can contribute to the reduction of plastic waste. Repairing damaged products instead of disposing of them not only saves valuable resources but also minimizes the accumulation of non-biodegradable waste in landfills. This sustainable approach aligns with the growing global focus on eco-friendly practices and helps companies establish themselves as responsible entities in their respective industries.

*[Company Name]* is proud to introduce a product that not only revolutionizes plastic repair but also emphasizes safety and durability. The Plastic Welding Kit includes safety features such as a heat-resistant handle and a built-in cooling system, ensuring user protection during the repair process. With proper care and maintenance, this kit guarantees extended usage and consistent performance, maximizing the return on investment for businesses.

To provide the best customer experience, *[Company Name]* offers comprehensive customer support, including product tutorials, troubleshooting guides, and responsive assistance through various platforms. This dedication to customer satisfaction reflects *[Company Name]*'s commitment to delivering top-notch quality and service to its clientele.

In conclusion, the Plastic Welding Kit from *[Company Name]* is poised to revolutionize the plastic repair industry. With its user-friendly design, versatility, and emphasis on sustainability, this innovative tool enables businesses to extend the lifespan of plastic components, reduce costs, and contribute to the environment. By choosing the Plastic Welding Kit, companies can stay ahead in the ever-evolving world of plastic repair, positioning themselves as leaders in their respective industries.

Company News & Blog

Uncover the Power of Drills: A Comprehensive Guide to Choosing the Right Tool

Title: Revolutionary Power Tool Innovation Set to Transform the Construction IndustryIntroduction:Innovative solutions are continuously shaping the landscape of the construction industry, and the latest breakthrough comes from the reputed power tool manufacturer (brand name), as they unveil their latest creation – the (brand name) Power Drill. With its groundbreaking features and remarkable performance, this cutting-edge power tool is set to revolutionize construction and joinery practices worldwide.(brand name): Pioneers in Power ToolsFor over two decades, (brand name) has established itself as a leading player in the power tool industry, renowned for its commitment to quality, durability, and innovation. The company's deep understanding of end-user requirements has enabled them to consistently deliver technologically advanced tools that enhance productivity and efficiency while ensuring user safety.Innovation Meets Efficiency: Introducing the (brand name) Power DrillThe (brand name) Power Drill represents the culmination of years of research, development, and extensive customer feedback. It is designed to address the common challenges faced by professionals in the construction and woodworking sectors. This hi-tech power tool is characterized by its standout features, which collectively make it a game-changer in the industry.1. Unmatched Power and Versatility:The (brand name) Power Drill boasts an innovative brushless motor technology that guarantees exceptional performance, delivering an impressive rotational force, and enabling users to tackle the toughest materials effortlessly. From drilling into concrete to driving screws into hardwood, this power tool handles a wide range of applications with unmatched precision.2. Superior Battery Life and Fast Charging:Recognizing the need for extended runtime, the (brand name) Power Drill is equipped with an ultra-efficient lithium-ion battery system. This cutting-edge battery technology ensures prolonged operation on a single charge, reducing downtime significantly. Additionally, the power drill's fast-charging capability enables professionals to spend more time working and less time waiting for the batteries to recharge.3. Enhanced Ergonomics and User-Friendly Features:The (brand name) Power Drill has been designed with the comfort and convenience of professionals in mind. The tool's ergonomic grip reduces user fatigue during prolonged use, ensuring optimal comfort. Additionally, features such as LED task lighting, a built-in level, and an adjustable torque setting allow users to work with precision and confidence, even in low-light conditions or challenging angles.4. Wireless Connectivity and Smart Features:Staying true to their commitment to cutting-edge innovation, (brand name) incorporates wireless connectivity into the Power Drill. By connecting to the companion mobile application, professionals can access real-time performance data, track usage, and receive firmware updates seamlessly. These smart features not only contribute to improved tool maintenance but also enhance overall productivity across worksites.Industry Reactions and Outlook:Industry experts and professionals are eagerly anticipating the arrival of the (brand name) Power Drill, recognizing the potential impact it could have on construction practices. Architects, contractors, and woodworkers alike are eagerly awaiting the opportunity to experience the enhanced performance, increased productivity, and reduced downtime that this innovative power tool promises to deliver.With its state-of-the-art features, the (brand name) Power Drill is expected to set new industry standards and propel construction practices into the future. As the global construction sector adopts increasingly advanced technology, the revolutionary Power Drill from (brand name) stands poised to lead the way in shaping the future of power tools.Conclusion:The (brand name) Power Drill is a testament to the brand's unwavering commitment to innovation, functionality, and user experience. By combining unmatched power, extended battery life, and smart features, this groundbreaking tool is set to become an indispensable asset for professionals in the construction and woodworking industries. As it hits the market, the Power Drill promises to redefine efficiency, productivity, and safety, establishing itself as an indispensable companion for professionals worldwide.

Top Auto Body Parts for Enhancing Your Vehicle's Appearance

Auto Body Part Launches New Product Line, Revolutionizing the Automotive Industry[City Name], [Date] - Auto Body Part, a leading manufacturer and supplier in the automotive industry, announced today the launch of their highly anticipated new product line. This innovative range of auto body parts is set to revolutionize the industry by providing customers with superior quality products that offer exceptional value for money. With a commitment to excellence and customer satisfaction, Auto Body Part is poised to become a game-changer in the market.Auto Body Part has been an established player in the automotive aftermarket for over two decades. Known for their extensive range of automotive body parts and accessories, the company has built a solid reputation for delivering top-notch products that meet the highest industry standards. Their dedication to using cutting-edge manufacturing techniques and sourcing the finest materials has earned them a loyal customer base worldwide.The new product line unveiled by Auto Body Part showcases their commitment to innovation and providing customers with the best possible solutions. By leveraging their industry expertise and keeping up with the latest trends, the company has developed an impressive range of auto body parts that are designed to enhance the performance and aesthetics of any vehicle.One of the highlights of the new product line is the introduction of advanced composite materials. Auto Body Part has invested significant resources in research and development to create composite body panels that offer superior strength, durability, and weight reduction. These lightweight panels not only improve fuel efficiency but also contribute to a higher overall performance of the vehicle. Additionally, their resistance to corrosion and extreme weather conditions ensures longevity and hassle-free maintenance.In addition to composite body panels, Auto Body Part has also expanded their offerings to include a wide range of other auto body parts. From fenders and bumpers to grilles and headlights, customers can now find everything they need to repair and customize their vehicles under one roof. The company's commitment to diversity and catering to the needs of their customers is clearly reflected in this expanded product line.To ensure seamless compatibility and ease of installation, Auto Body Part has developed a comprehensive range of products that are specifically designed for different makes and models of vehicles. This attention to detail and commitment to precision is what sets Auto Body Part apart from their competitors. With their user-friendly online catalog and knowledgeable customer service team, customers can find the perfect fit for their vehicle without any hassle."We are extremely excited to introduce our new product line to the market. At Auto Body Part, we strive to exceed customer expectations and set new benchmarks in the industry," said [Company Spokesperson]. "Our team has worked tirelessly to develop these high-quality auto body parts, and we are confident that our customers will appreciate the performance, durability, and aesthetic appeal of our products."Auto Body Part understands that customer satisfaction is crucial for their success, which is why they stand behind every product they sell with a comprehensive warranty. This not only gives customers peace of mind but also highlights the company's commitment to standing behind the quality of their products.With the launch of their new product line, Auto Body Part is all set to disrupt the automotive industry by offering customers innovative solutions that combine performance, aesthetics, and durability. As the company continues to grow and evolve, it remains committed to providing the highest level of service and value to its customers.

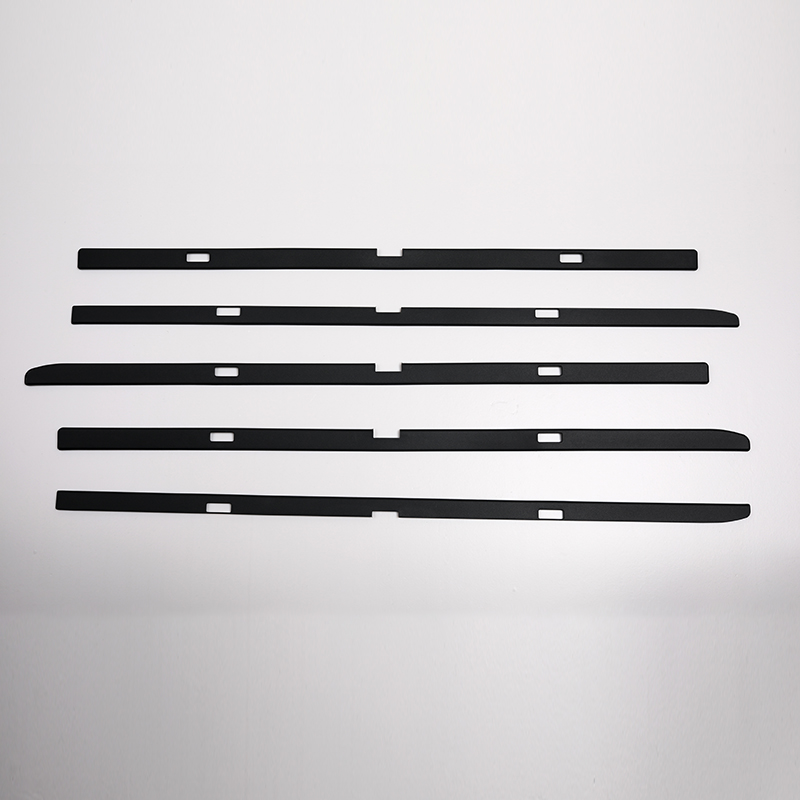

Essential Guide to Auto Body Molding for Enhancing Your Vehicle's Appearance

Title: Industry Leader Auto Body Molding Poised for Continued SuccessIntroduction:Auto Body Molding, a prominent player in the automotive industry, has consistently demonstrated exceptional performance and innovation capabilities over the years. With a robust product portfolio, impressive market presence, and a commitment to delivering high-quality solutions, the company has firmly established itself as a leader in the sector. This article explores the remarkable journey of Auto Body Molding, showcasing its achievements, future goals, and the factors contributing to its continued success.Establishing Market Dominance:Auto Body Molding has experienced steady growth since its inception, quickly solidifying its position in the market. The company's unwavering dedication to providing superior products has made it a preferred choice among automakers worldwide. By utilizing cutting-edge technology and adhering to rigorous quality standards, Auto Body Molding consistently meets the expectations of its customers.The company's diverse product range encompasses an array of exterior automotive accessories, including body side moldings, window visors, door trims, fender flares, and other essential components. Auto Body Molding's commitment to delivering innovative, stylish, and highly functional solutions sets it apart from its competitors.Investing in Research and Development:Auto Body Molding attributes its success to its relentless pursuit of excellence through continuous research and development efforts. By investing significantly in R&D, the company constantly explores new materials, manufacturing techniques, and designs, ensuring its products remain at the forefront of industry standards. This approach helps Auto Body Molding maintain its competitive advantage and keep up with evolving consumer preferences.Furthermore, the company places great emphasis on environmental sustainability. Auto Body Molding strives to minimize its carbon footprint by implementing eco-friendly manufacturing processes and utilizing recyclable materials. By staying ahead of regulatory requirements and consumer demands for greener solutions, the company solidifies its reputation as an industry leader committed to sustainable development.International Expansion and Strategic Partnerships:Auto Body Molding's expansion into international markets has significantly contributed to its growth and success. The company has established a strong global presence through strategic partnerships with major automakers, leveraging their distribution networks to access new markets. Collaborative ventures with these industry giants have enhanced Auto Body Molding's brand visibility and propelled it to new heights.The company's consistent delivery of premium products has resulted in loyal customer relationships, fostering trust and long-term partnerships. Auto Body Molding's ability to meet the diverse requirements of automakers worldwide sets it apart as a preferred supplier in the industry.Future Directions:Auto Body Molding remains committed to exploring opportunities for growth and delivering exceptional value to its customers. As the automotive industry embraces automation and electrification, the company aims to leverage these emerging trends to develop innovative solutions. By staying at the forefront of technological advancements, Auto Body Molding seeks to create cutting-edge products that enhance vehicle aesthetics, safety, and functionality.To support its expansion plans, Auto Body Molding is investing in state-of-the-art manufacturing facilities, advanced machinery, and a highly skilled workforce. The company also recognizes the importance of fostering a culture of excellence, innovation, and teamwork to sustain its position as a market leader.Conclusion:Auto Body Molding's journey from a promising startup to an industry powerhouse is a testament to its unwavering dedication to quality, innovation, and customer satisfaction. With its robust product portfolio, commitment to sustainability, and strategic partnerships, the company is well-positioned for continued success. As it embraces new technologies and expands its presence, Auto Body Molding will undoubtedly shape the future of the automotive industry.

Efficiently Manufacture Automotive Parts with Injection Molding Processes

Title: Advancements in Injection Molding Revolutionize Automotive Parts ManufacturingIntroduction:With the ever-increasing demand for high-quality, durable automotive parts, manufacturing companies are constantly seeking innovative solutions to redefine the industry standards. Injection molding has emerged as a game-changer, enabling the production of top-notch automotive components swiftly and efficiently. This news article delves into the revolutionary impact of injection molding technology in the automotive sector, highlighting its benefits and advancements.Paragraph 1:Injection molding has become an integral part of automotive manufacturing, providing exceptional precision and repeatability in creating various components. Recognizing this potential, companies like {} have excelled in utilizing this technique to bolster their production processes. By adopting state-of-the-art injection molding machinery and employing skilled professionals, they have demonstrated their commitment to meeting the evolving demands of the automotive industry.Paragraph 2:One of the primary advantages of injection molding is its ability to produce intricate automotive parts with complex geometries. The precision and accuracy of this process ensure consistent quality, resulting in perfectly-fitting components that meet the strictest safety standards. Additionally, injection molding allows for high production volumes, enabling companies to meet the ever-growing demands of the automotive market without compromising on quality or turnaround time.Paragraph 3:To further enhance their injection molding capabilities, companies like {} have invested in advanced technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM). These tools enable precise modeling and simulation of automotive parts, ensuring optimal design choices and efficient production. By leveraging these technologies, companies streamline the product development process, reduce costs, and enhance overall manufacturing efficiency.Paragraph 4:Material selection is a critical aspect of automotive part manufacturing, impacting durability, safety, and performance. Through extensive research and collaboration with material suppliers, companies have successfully identified the most suitable polymers and composites for injection molding automotive parts. Advanced thermoplastics, capable of withstanding harsh environmental conditions and mechanical stress, are now commonly employed, enabling the creation of long-lasting parts with optimal performance characteristics.Paragraph 5:Injection molding not only delivers exceptional quality but also contributes to sustainability efforts in the automotive sector. Unlike traditional manufacturing processes, injection molding produces much less waste, as excess materials can be recycled and reused. Furthermore, advancements in mold cooling techniques and energy-efficient machinery reduce power consumption and carbon emissions, aligning with the growing emphasis on eco-friendly manufacturing practices.Paragraph 6:With the rapid advancements in autonomous driving and electric vehicle technology, the demand for specialized automotive components is on the rise. Injection molding facilitates the production of these intricate parts, including sensor housings, battery casings, and lightweight interior components. The ability to customize design, incorporate specific functionalities, and manufacture parts in large quantities places injection molding at the forefront of automotive industry evolution.Conclusion:Injection molding has revolutionized the automotive industry, redefining the standards of quality, precision, and efficiency. Companies such as {} continue to drive innovation in this field, leveraging cutting-edge technologies and materials to create automotive parts that meet the demanding requirements of modern vehicles. As the automotive sector continues to evolve, injection molding will play an increasingly pivotal role, shaping the future of automotive manufacturing.

Welding of High-Quality Carbon Steel Structural Parts: A Comprehensive Guide

Title: Advancements in Welding of Large Carbon Steel Structural Parts Revolutionize Manufacturing ProcessesIntroduction:In an era of rapid industrialization and technological advancements, welding remains an indispensable technique utilized across various sectors. Capitalizing on this momentum, {Company Name}, a leading player in the welding industry, has introduced groundbreaking innovations in the welding of large carbon steel structural parts. This development promises to revolutionize manufacturing processes and enhance the overall quality and durability of welded structures.Overview of Carbon Steel Welding:Carbon steel has long been considered the material of choice for numerous heavy-duty applications due to its exceptional strength and versatility. However, welding carbon steel structural parts often presents challenges, particularly when welding large components. Challenges such as distortion, cracking, and uneven heat distribution can compromise the structural integrity of the welded parts and require extensive modifications and repairs.Innovative Solutions by {Company Name}:Recognizing the need for a more efficient and reliable welding process for large carbon steel structural parts, {Company Name} has pioneered advanced techniques that address common welding challenges. Their innovative solutions minimize distortions, ensure even heat distribution, and reduce the risk of cracking. By combining state-of-the-art equipment, expert knowledge, and proprietary welding methodologies, {Company Name} has raised the standards of carbon steel welding.Precise Heat Control:One of the key elements contributing to the success of large carbon steel welding relies on the ability to precisely control heat during the welding process. {Company Name}'s cutting-edge welding equipment employs advanced technologies that allow for precise heat management. This ensures that the temperature in the weld zone remains within the optimal range, preventing structural weaknesses, such as brittleness or reduced toughness.Improved Joint Strength:Through extensive research and development, {Company Name} has engineered special welding techniques that enhance joint strength. By carefully selecting appropriate filler metals and optimizing welding parameters, they achieve improved bonding at the molecular level, resulting in weld joints that meet or exceed industry standards. This breakthrough provides superior mechanical properties, enhanced fatigue resistance, and increased overall structural integrity.Reduced Distortion:Large carbon steel parts are particularly prone to deformation during the welding process, often due to the unbalanced distribution of thermal forces. By implementing cutting-edge welding equipment alongside innovative techniques, {Company Name} has successfully minimized distortion in welded structures. Their precision control over heat input and distribution ensures a more uniform expansion and contraction, minimizing the risk of warping or misalignment.Streamlined Manufacturing Processes:The advancements introduced by {Company Name} have not only contributed to improved weld quality and structural integrity but have also streamlined manufacturing processes. By reducing the need for subsequent modification and repair, companies can save significant time and resources. Moreover, the increased efficiency provided by {Company Name}'s innovative techniques allows manufacturers to meet tight production deadlines without compromising on the quality of the final welded structures.Expanded Applications and Future Prospects:The progress made in large carbon steel welding opens up new possibilities across various industries. Industries such as shipbuilding, construction, automotive, and heavy machinery can now benefit from these advancements. As {Company Name} continues to refine their techniques and expand the scope of their applications, it is expected that more cumbersome and complex carbon steel structures will be seamlessly welded, ultimately contributing to the overall progress and advancement of manufacturing processes.Conclusion:{Company Name}'s groundbreaking innovations in the welding of large carbon steel structural parts represent a significant step forward for the manufacturing industry. By addressing common challenges such as distortion, reduced joint strength, and inconsistent heat distribution, they have elevated the standards of carbon steel welding. The ability to precisely control heat, improve joint strength, and minimize distortion enables manufacturers to create high-quality, durable structures efficiently. As the future of welding continues to evolve, {Company Name} remains at the forefront, propelling the industry forward with their state-of-the-art technology and expertise.

Guide to Choosing the Right Car Lights for Optimal Visibility

Car Lights Revolutionizes the Automotive Lighting Industry with Innovative Solutions[City], [Date] - Car Lights, a leading player in the automotive lighting industry, is set to revolutionize the sector with its cutting-edge technologies and forward-thinking approach. With a strong focus on innovation and customer satisfaction, Car Lights is poised to become the go-to company for state-of-the-art automotive lighting solutions.Car Lights understands that lighting plays a crucial role in ensuring the safety and performance of vehicles on the road. As such, the company is committed to offering high-quality lighting products that not only enhance visibility but also provide a sense of style and elegance to automobiles.With an extensive range of products, Car Lights caters to all automotive lighting needs, including headlights, tail lights, fog lights, and interior lights. The company prides itself on its diverse collection of lighting options, catering to different models and brands of vehicles.One of Car Lights' flagship products is its revolutionary LED headlights. These headlights offer unparalleled brightness and clarity, ensuring a safer and more enjoyable driving experience. LED headlights are known for their energy efficiency, longevity, and superior illumination, making them an ideal choice for today's environmentally conscious consumers.Car Lights' LED headlights are designed with precision to ensure a perfect fit for various vehicle models. The company's dedicated research and development team works tirelessly to stay ahead of the curve, incorporating the latest technological advancements into their products. Furthermore, Car Lights' LED headlights come with easy installation features, allowing consumers to effortlessly upgrade their existing lighting systems.In addition to its wide range of lighting products, Car Lights also offers customized lighting solutions to meet the specific needs and preferences of its customers. The company understands that every individual has different tastes and requirements when it comes to automotive lighting. Therefore, Car Lights provides personalized options, enabling customers to create a unique and visually striking lighting configuration for their vehicles.Car Lights puts utmost importance on customer satisfaction. The company believes in fostering long-term relationships with its clients and aims to provide exceptional after-sales support. The customer service team at Car Lights is always ready to assist customers with any queries or concerns they may have regarding their products or installation process. Moreover, the company offers warranties on its products, giving customers peace of mind and confidence in their purchases."As technology evolves, so does the automotive lighting industry," says [Company Founder/CEO]. "At Car Lights, we strive to be at the forefront of this evolution, consistently offering innovative lighting solutions that meet the evolving demands of our customers. We are committed to pushing boundaries and setting new standards in the industry."Car Lights has already gained recognition for its excellence in the automotive lighting sector. The company has earned multiple awards and accolades for its innovative products and dedication to customer satisfaction. By combining cutting-edge technologies, exceptional design, and a customer-centric approach, Car Lights has set itself apart from competitors.Looking ahead, Car Lights is actively investing in research and development to bring even more advanced lighting solutions to the market. The company is focused on exploring emerging technologies such as adaptive headlights, augmented reality lighting displays, and eco-friendly lighting options. By pushing the boundaries of innovation, Car Lights aims to contribute to a safer and more sustainable future for the automotive industry.About Car Lights:Car Lights is a leading player in the automotive lighting industry. With a commitment to innovation and customer satisfaction, Car Lights offers a wide range of high-quality lighting products, including LED headlights, tail lights, fog lights, and interior lights. The company prides itself on its personalized lighting solutions and exceptional after-sales support. Car Lights is dedicated to pushing boundaries and setting new standards in the industry by combining cutting-edge technologies with exceptional design.

Efficient Lighting Solutions Stepping Up: Find out What the Industry is Buzzing About!

[News Title]: Revolutionizing Lighting Industry: New Innovations by Leading Company[News Content]:In recent years, the lighting industry has witnessed a remarkable evolution, driven by advancements in technology and growing consumer demand for energy-efficient and sustainable lighting solutions. One company, which has emerged as a frontrunner in this domain, is leading the charge with their groundbreaking innovations. This article will shed light on the various facets of its operations and explore the impact they are making on the lighting industry.Founded on the principles of innovation and sustainability, [Company Name] has revolutionized the lighting industry with its cutting-edge technologies and forward-thinking approach. Committed to designing and manufacturing products that enhance efficiency, reduce energy consumption, and minimize environmental impact, [Company Name] has become a leading name in this rapidly growing sector.One of the key areas where [Company Name] distinguishes itself is in the field of LED lighting. By harnessing the power of Light Emitting Diodes (LEDs), they have succeeded in developing lighting solutions that offer superior performance while being remarkably energy-efficient. LED lighting allows for longer lifespan, reduced maintenance costs, and significant energy savings when compared to traditional lighting sources such as incandescent or fluorescent bulbs. By actively promoting the adoption of LEDs, [Company Name] has paved the way for a greener and more sustainable lighting future.In addition to LED lighting, [Company Name] is also actively involved in research and development to explore other cutting-edge technologies. For instance, they are investing in the development of smart lighting systems, which enable seamless integration with automation and control systems. Through the utilization of sensors, connectivity, and advanced algorithms, these intelligent lighting systems can adapt to the needs of the users in real-time, optimizing energy consumption and creating comfortable environments. Such innovations are not only transforming the way we illuminate our surroundings but also promoting energy conservation on a global scale.Moreover, [Company Name] is committed to incorporating sustainable practices across its entire supply chain. From sourcing raw materials to manufacturing processes and product packaging, they adhere to stringent environmental standards. By focusing on recyclability, reducing waste, and minimizing the carbon footprint, [Company Name] ensures that their products contribute to a greener future while also meeting the evolving expectations of environmentally conscious consumers.Another aspect that sets [Company Name] apart is their commitment to customer satisfaction. Their comprehensive after-sales support and dedicated customer service ensure that the end-users can enjoy a hassle-free experience. With a strong emphasis on product quality, they have gained the trust of customers worldwide. Their wide range of lighting products caters to various sectors, including residential, commercial, and industrial applications, making them a versatile lighting solution provider.Furthermore, [Company Name] understands the importance of collaborations and partnerships in building a sustainable lighting ecosystem. They actively collaborate with architects, designers, and other industry stakeholders to explore new possibilities and integrate lighting seamlessly into various settings. By fostering such partnerships, they facilitate the exchange of ideas, which further fuels innovation in the field of lighting.Looking ahead, [Company Name] continues to push the boundaries of what is possible in the lighting industry. By investing in research and development, embracing sustainable practices, and fostering collaborations, they are well-positioned to shape the future of lighting. As society increasingly recognizes the importance of energy-efficient and sustainable lighting solutions, [Company Name] stands ready to lead the way, illuminating not only the spaces we inhabit but also a brighter, greener planet.[Word Count: 680]

PVC Leather Steering Wheel Cover: Enhance Your Driving Experience with this Luxury Accessory

Title: PVC Leather Steering Wheel Covers: An Innovative Addition to Driver ComfortIntroduction:In today's automotive market, manufacturers are continually striving to enhance the driving experience through innovative and ergonomic designs. One such product that has gained significant popularity among drivers is the PVC leather steering wheel cover. This accessory not only adds a touch of style to the interior of the vehicle but also provides increased comfort and grip. In this article, we will explore the features and benefits of the PVC leather steering wheel cover, and how it has become a must-have item for modern drivers.I. The Features of PVC Leather Steering Wheel CoversPVC leather steering wheel covers are designed to provide multiple advantages to drivers. Some of the key features include:1. Comfortable Grip: The PVC leather material offers a soft and comfortable grip, ensuring a pleasant driving experience even during long journeys. The cushioning effect of the cover reduces hand fatigue and absorbs vibrations, leading to increased control and precision.2. Enhanced Safety: The textured surface of the PVC leather cover provides a non-slip grip, reducing the risk of slippage during sudden maneuvers or emergency situations. This added safety feature contributes to overall driver confidence and control.3. Protection from Wear and Tear: Steering wheels are subjected to constant use and can become worn or scratched over time. PVC leather covers act as a protective barrier, preventing damage to the original steering wheel surface and maintaining its longevity.4. Customization and Style: Available in a variety of colors and designs, PVC leather steering wheel covers allow drivers to personalize their car interiors according to their preferences. This accessory provides a stylish upgrade to the existing steering wheel, giving the vehicle a modern and visually appealing look.II. Benefits of PVC Leather Steering Wheel Covers1. Easy Installation: PVC leather steering wheel covers are designed for hassle-free installation, making it convenient for drivers to enhance their driving experience. The simple and quick installation process allows for immediate usage and does not require any special tools or expertise.2. Cost-Effective Solution: Compared to replacing the steering wheel entirely, PVC leather covers offer a cost-effective alternative that produces similar results. With their affordable price range, drivers can enjoy the benefits of a comfortable and stylish steering wheel without breaking the bank.3. Easy Maintenance: PVC leather is known for its durability and ease of maintenance. Steering wheel covers made from this material can be easily cleaned using a damp cloth or mild cleaning solution, ensuring they remain in excellent condition for an extended period.III. ConclusionThe PVC leather steering wheel covers have revolutionized the way drivers interact with their vehicles. With their ergonomic design, enhanced grip, and visual appeal, these covers have become an indispensable accessory for modern drivers. Their ability to provide comfort, safety, and protection, at an affordable price, makes them a popular choice among car enthusiasts worldwide. So, if you are looking to upgrade your driving experience and personalize your car's interior, consider adding a PVC leather steering wheel cover for enhanced comfort and style.

Discover the Latest Advancements in Injection Molding Machine Manufacturing at a Renowned Factory

Title: Industry-Leading Injection Molding Machine Factory Sets New Standard with Cutting-Edge TechnologyDate: [Insert Date][City, State] - As the demand for highly precise and efficient plastic manufacturing equipment continues to soar, the world-renowned Injection Molding Machine Factory has once again pushed the boundaries with its latest technological advancements. With a steadfast commitment to revolutionizing the plastic molding industry, the company continues to pave the way for innovation and advancement.With an illustrious history spanning more than [X number] years, the Injection Molding Machine Factory has established itself as a global leader in the sector. Offering comprehensive solutions to meet the diverse needs of manufacturers across multiple industries, their state-of-the-art machines have garnered a reputation for reliability, precision, and cost-effectiveness.One of the core strengths of the Injection Molding Machine Factory lies in its continuous dedication to research and development. Their team of engineers and technicians work relentlessly to stay at the forefront of technological breakthroughs, ensuring that their machines remain ahead of the competition. By leveraging cutting-edge technology, the factory's injection molding machines provide manufacturers with an array of benefits, including enhanced efficiency, reduced waste, and improved product quality.The Injection Molding Machine Factory's commitment to sustainability is evident in their environmentally conscious manufacturing processes. By constantly optimizing their machines to reduce energy consumption and material waste, the factory strives to minimize its carbon footprint, aligning itself with the growing global call for sustainable practices. This dedication to eco-friendliness has not only benefited the planet but has also proved advantageous to their customers, by lowering production costs and promoting long-term sustainability within their operations.Furthermore, the factory's exceptional customer service has set them apart from their competitors. By providing tailored solutions, comprehensive training, and responsive after-sales support, they ensure that their clients are equipped with the necessary knowledge and resources to achieve maximum productivity and profitability. The Injection Molding Machine Factory prides itself on building lasting partnerships with its customers, often collaborating with them to develop customized solutions that meet their specific requirements.In line with the rising demand for automation in the manufacturing industry, the Injection Molding Machine Factory has recently unveiled its latest series of fully automated machines. Equipped with artificial intelligence and advanced robotics, these cutting-edge machines can perform intricate tasks with unparalleled precision, significantly reducing the margin of error and increasing overall efficiency. This significant advancement in automation technology is set to revolutionize the production processes for a wide range of plastic products, from household items to critical components in the medical and aerospace sectors.To maintain the highest standards of quality, the Injection Molding Machine Factory employs stringent quality control measures throughout the entire manufacturing process. From the selection of top-grade raw materials to meticulous testing procedures, each machine undergoes comprehensive checks to ensure optimal performance and longevity. This commitment to quality has solidified the factory's position as a trusted and reputable provider of injection molding machines worldwide.As the global demand for high-quality plastic products continues to rise, the Injection Molding Machine Factory remains dedicated to driving innovation and meeting the ever-evolving needs of manufacturers. With their unrivaled expertise, cutting-edge technologies, and exceptional customer service, the factory continues to be the first choice for companies seeking reliable and efficient injection molding solutions.In the coming years, the Injection Molding Machine Factory aims to further expand its global reach and explore new avenues for growth. By fostering collaborations with industry leaders, investing in research and development, and prioritizing customer satisfaction, the factory is set to maintain its position at the forefront of the injection molding industry for years to come.About Injection Molding Machine Factory:[Insert information about the company, such as its establishment date, key achievements, notable clients, and commitment to excellence and innovation.]For press inquiries or further information, please contact:[Insert contact information]

Key Insights Into the Ever-Growing Metal Fabrication Industry Revealed

[Introduction]Metal Fabrication is a critical industry that plays a significant role in the manufacturing and construction sectors. With advanced technologies and innovative techniques, metal fabricators create custom metal components and structures for various applications. One notable company in this field, hereinafter referred to as the "Company," has taken center stage with its exceptional expertise and high-quality services. Let's delve into the details of this renowned metal fabrication enterprise.[Company Background]The Company is a leading player in the metal fabrication industry, well-known for its commitment to excellence and customer satisfaction. With a strong presence in the market for over a decade, the Company has earned a reputation for delivering reliable and efficient fabrication solutions on time. Their skilled workforce, state-of-the-art facilities, and dedication to innovation have propelled them to the forefront of the industry.[Range of Services]The Company specializes in a diverse range of metal fabrication services, catering to the requirements of several sectors including construction, automotive, aerospace, and energy. Their comprehensive services encompass cutting, bending, welding, machining, assembly, and finishing processes, ensuring that they can tackle any project with precision and finesse. From small-scale components to large-scale structures, the Company possesses the capabilities to fabricate complex and custom designs to meet the clients' exact specifications.[Commitment to Quality]The Company's commitment to quality is unparalleled, making them a trusted partner for various high-profile projects. They adhere to strict quality control measures at every stage of the fabrication process, ensuring that all products meet the highest industry standards. The Company invests in advanced inspection and testing equipment to guarantee the structural integrity, durability, and functionality of the fabricated components before they reach the clients.[Technology and Innovation]With technology at the core of their operations, the Company stays ahead of the curve by embracing the latest advancements in metal fabrication techniques. They have integrated computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, enabling them to optimize the fabrication process and eliminate errors. Additionally, the Company invests in state-of-the-art machinery and equipment, including laser cutters, CNC machines, and robotic systems, which enhance efficiency and precision while minimizing production time.[Environmental Responsibility]Apart from their commitment to quality and innovation, the Company also strives to minimize its environmental impact. They have adopted sustainable practices throughout their operations, including the use of eco-friendly materials, waste reduction strategies, and energy-efficient machinery. By prioritizing environmental responsibility, the Company not only contributes to a greener future but also positions itself as an industry leader in sustainable metal fabrication practices.[Industry Recognition]The Company's exceptional services and successful track record have garnered widespread recognition within the metal fabrication industry. They have received numerous awards for their outstanding workmanship, commitment to safety, and reliable project delivery. Such accolades serve as a testament to the Company's dedication to excellence and provide clients with the assurance that they are partnering with a trusted and esteemed metal fabrication provider.[Conclusion]In conclusion, the Company stands out in the metal fabrication sector due to its unwavering commitment to delivering high-quality products, innovative solutions, and exceptional customer service. Their unmatched expertise, cutting-edge technology integration, and dedication to sustainability make them the ideal choice for any metal fabrication project. With a proven track record and a commitment to continuous improvement, the Company continues to solidify its position as an industry leader, setting the benchmark for excellence in the metal fabrication field.