Top CNC Plastic Machining Prototype: Breaking Down the Newsworthy Details

By:Admin

Introduction:

In recent years, advancements in CNC plastic machining prototypes have pushed the boundaries of innovation in the manufacturing industry. These cutting-edge technologies have revolutionized traditional manufacturing processes, enabling companies to develop high-quality, precision plastic components. This article explores the recent breakthrough in CNC plastic machining prototypes and its potential to transform the industry.

In a bid to stay at the forefront of the rapidly evolving manufacturing landscape, [Company Name], a leader in cutting-edge technology solutions, has recently introduced an unprecedented CNC plastic machining prototype. The prototype is poised to redefine the manufacturing process by offering enhanced precision, efficiency, and cost-effectiveness that were previously unattainable.

Unveiling the Revolutionary CNC Plastic Machining Prototype:

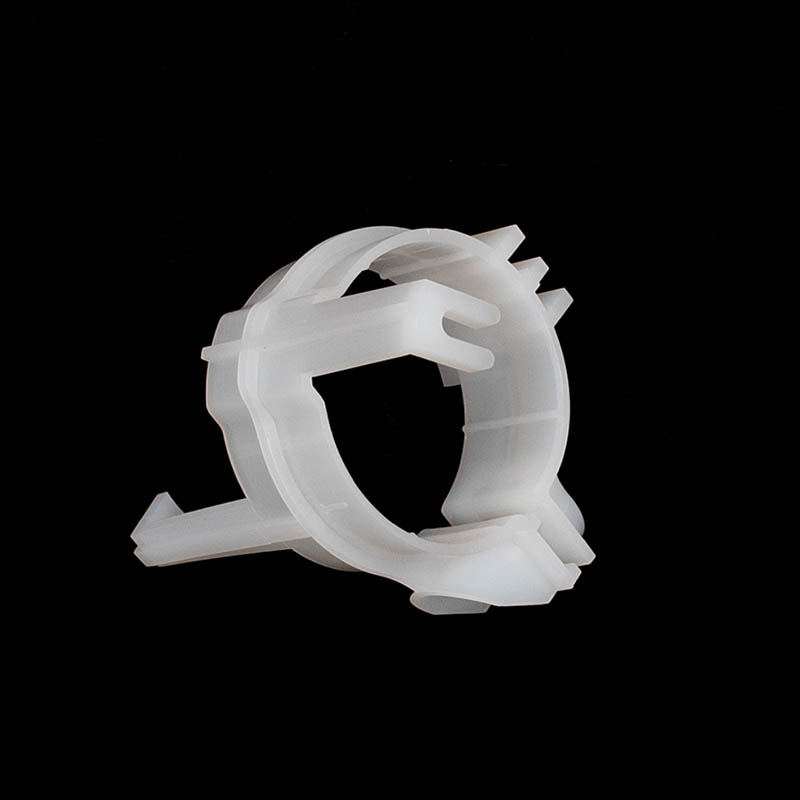

The groundbreaking CNC plastic machining prototype developed by [Company Name] leverages the latest advancements in machine learning algorithms, robotics, and material science. This combination enables the efficient production of intricate plastic parts, reducing lead times and eliminating the need for expensive tooling.

The new prototype incorporates highly sophisticated computer numerical control (CNC) systems that accurately execute commands for cutting, shaping, and fabricating plastic materials. Through meticulous programming and specialized tooling, this technology ensures consistent output, surpassing traditional manufacturing techniques in terms of precision and reproducibility.

Unmatched Precision and Quality:

One of the key advantages of this CNC plastic machining prototype is its ability to deliver unparalleled precision and product quality. By eliminating human errors and minimizing material waste, this technology ensures consistent and reliable production outcomes. This level of precision greatly benefits sectors such as aerospace, automotive, electronics, and medical, where intricate plastic components are crucial for optimal performance.

Efficiency and Cost-effectiveness:

The CNC plastic machining prototype significantly reduces manufacturing lead times and costs associated with traditional methods. With its automated processes and rapid production capabilities, companies can obtain functional plastic prototypes within a fraction of the time compared to conventional production methods. This enhanced efficiency translates into reduced project costs, enabling companies to bring products to market faster and gain a competitive edge.

Customization and Versatility:

The adaptability of the CNC plastic machining prototype allows for customization and versatility in the production process. The technology accommodates a wide range of plastic materials, including ABS, polycarbonate, nylon, and more. Moreover, the precision offered by this prototype enables the fabrication of complex geometries and fine details, catering to various design specifications.

Sustainability and Waste Reduction:

In addition to the numerous functional benefits, this CNC plastic machining prototype contributes to a more sustainable manufacturing process. Through its ability to minimize material waste and optimize resource utilization, the technology supports environmentally conscious production practices. By reducing the amount of raw material required and minimizing energy consumption, manufacturers can significantly reduce their environmental footprint.

Future Implications and Industry Impact:

The introduction of this CNC plastic machining prototype represents a transformative juncture in the manufacturing industry. The advanced precision, efficiency, and cost-effectiveness it brings may significantly reshape the way companies fabricate plastic components. These advancements can drive innovation, streamline processes, and empower manufacturers to meet increasing demands swiftly.

[Company Name]'s CNC plastic machining prototype signifies a remarkable achievement in pushing the boundaries of manufacturing capabilities. As industries adopt this cutting-edge technology, they can expect greater product quality, reduced costs, and accelerated time-to-market. The future of manufacturing has arrived, promising a more sustainable and efficient era of plastic component fabrication.

Conclusion:

The development of the CNC plastic machining prototype by [Company Name] has introduced a disruptive force to the manufacturing industry. With unrivaled precision, efficiency, and cost-effectiveness, this technology holds immense potential for transforming production processes and meeting the evolving needs of industries worldwide. As we embrace this groundbreaking technology, we can anticipate a future where manufacturing reaches new heights of advancement, driving innovation and growth.

Company News & Blog

Guide to Using a Plastic Welding Kit for Efficient Repairs

**Plastic Welding Kit: Revolutionizing Repairs in the Plastics Industry***[Company Name]*, a leading manufacturer in the field of plastic repair solutions, is set to redefine the industry with its latest innovation—the Plastic Welding Kit. This advanced tool offers a reliable and efficient method for repairing, joining, and reinforcing various plastic materials, providing a cost-effective and sustainable solution.Plastic is one of the most versatile materials used in various industries, from automotive to construction and even household items. However, when damaged, plastic components often require replacement, leading to increased costs and generating unnecessary waste. The Plastic Welding Kit aims to address this issue by enabling users to repair damaged parts, prolonging their lifespan and reducing the environmental footprint.The Plastic Welding Kit consists of a robust handheld welding unit, an assortment of specialized plastic welding rods, and a set of accessories for optimal repair performance. The welding unit features a temperature control system, allowing users to precisely apply heat to the damaged plastic, ensuring proper melting and fusion. This ensures a strong and durable bond, similar to the original material.The versatility of the Plastic Welding Kit is unmatched, as it can weld various types of plastic, including ABS, PVC, polycarbonate, polypropylene, and many more. With the ability to repair a wide range of plastics, this kit serves as an essential tool for professionals in industries such as automotive repair, manufacturing, and even DIY enthusiasts.The key benefit of this innovative kit lies in its ease of use. Even novices can quickly grasp its operation, thanks to the comprehensive user manual provided by *[Company Name]*. Following simple steps, users can repair cracks, holes, and tears in plastic components with precision and efficiency. By adopting the Plastic Welding Kit, industries can save time and money by avoiding costly replacements.Moreover, by using the Plastic Welding Kit, companies can contribute to the reduction of plastic waste. Repairing damaged products instead of disposing of them not only saves valuable resources but also minimizes the accumulation of non-biodegradable waste in landfills. This sustainable approach aligns with the growing global focus on eco-friendly practices and helps companies establish themselves as responsible entities in their respective industries.*[Company Name]* is proud to introduce a product that not only revolutionizes plastic repair but also emphasizes safety and durability. The Plastic Welding Kit includes safety features such as a heat-resistant handle and a built-in cooling system, ensuring user protection during the repair process. With proper care and maintenance, this kit guarantees extended usage and consistent performance, maximizing the return on investment for businesses.To provide the best customer experience, *[Company Name]* offers comprehensive customer support, including product tutorials, troubleshooting guides, and responsive assistance through various platforms. This dedication to customer satisfaction reflects *[Company Name]*'s commitment to delivering top-notch quality and service to its clientele.In conclusion, the Plastic Welding Kit from *[Company Name]* is poised to revolutionize the plastic repair industry. With its user-friendly design, versatility, and emphasis on sustainability, this innovative tool enables businesses to extend the lifespan of plastic components, reduce costs, and contribute to the environment. By choosing the Plastic Welding Kit, companies can stay ahead in the ever-evolving world of plastic repair, positioning themselves as leaders in their respective industries.

Discover the Benefits of a Quality Leather Steering Wheel Cover for Your Car

[Title]: Unveiling a Premium Leather Steering Wheel Cover - Enhancing the Driving Experience[Subtitle]: Introducing a Game-Changer in Car Accessories for Ultimate Style and Comfort[Company Introduction]:In the pursuit of innovation and excellence, {Company Name} is proud to launch its latest addition to the automotive accessories market - a premium leather steering wheel cover crafted to revolutionize the driving experience. With a commitment to delivering products of the highest quality and functionality, {Company Name} has established itself as a trusted brand among car enthusiasts and professionals alike.[Paragraph 1]:The steering wheel is an integral part of any vehicle, playing a crucial role in ensuring safety, control, and an overall enjoyable driving experience. Recognizing this, {Company Name} took upon itself to design a steering wheel cover that not only protects the wheel from wear and tear but elevates the aesthetic appeal and comfort for drivers as well.[Paragraph 2]:Crafted from the finest leather materials, the new steering wheel cover offers a luxurious feel combined with enhanced grip and durability. The ergonomic design ensures a snug fit on the wheel, making it suitable for a wide range of vehicles, including cars, trucks, and SUVs. The cover also features precision stitching, offering a seamless finish that complements the existing interior of any vehicle.[Paragraph 3]:One of the standout features of the leather steering wheel cover is its temperature control properties. The superior leather helps regulate the temperature of the wheel, making it cool to the touch during summer months and warm during colder seasons. This innovative aspect ensures maximum comfort for the driver, reducing any discomfort caused by extreme weather conditions.[Paragraph 4]:Moreover, {Company Name} has prioritized safety in the design of the steering wheel cover. The non-slip surface provides an enhanced grip, reducing the chances of the driver's hands slipping during maneuvers. This anti-slip feature, combined with the added thickness of the cover, promotes a safer driving experience by minimizing hand fatigue and improving overall control.[Paragraph 5]:Installation of the leather steering wheel cover is a breeze, and it can easily be secured within minutes. The cover's versatility ensures compatibility with most standard-sized steering wheels, catering to a diverse range of users. Whether a professional driver looking for prolonged comfort or an individual seeking a touch of luxury, the steering wheel cover promises to enhance every driving journey.[Paragraph 6]:Beyond its functional features, the leather steering wheel cover is also designed to augment the visual appeal of the vehicle's interior. Available in a variety of colors, including classic black, sleek gray, and timeless brown, the cover adds a touch of sophistication and style to any car's cabin. The refined exterior and attention to detail make this accessory a must-have for those seeking to personalize their vehicles.[Paragraph 7]:{Company Name} prides itself on offering high-quality products at competitive prices, and the leather steering wheel cover is no exception. With affordability, functionality, and durability at the forefront, customers can trust that they are investing in a long-lasting accessory that will enhance their driving experience for years to come. [Paragraph 8]:In conclusion, the launch of the leather steering wheel cover by {Company Name} represents a significant step forward in car accessory innovation. With its premium construction, exceptional functionality, and luxurious aesthetics, this product is set to become a game-changer in the industry. Drivers around the world can now enjoy the ultimate combination of style, comfort, and safety, making every road trip an unforgettable experience.

Chinese Factory Transforms into CNC Facility, Catering to TS16949 Standards

Title: Chinese TS16949 Factory Transforms into CNC Manufacturing HubIntroduction:In a strategic move towards technological innovation and efficiency, a leading Chinese TS16949-certified factory has recently undergone a significant transformation, repositioning itself as a multi-functional CNC manufacturing hub. This ambitious transition is aimed at expanding capabilities, optimizing production processes, and offering a wider range of services to meet the evolving demands of both domestic and international markets. With this transformation, the factory seeks to reinforce its commitment to precision engineering and cutting-edge solutions, solidifying its position as a key player within the CNC manufacturing industry.Article:In response to the accelerating pace of technological advancements, the Chinese TS16949-certified factory has made a strategic decision to embrace CNC manufacturing technologies. Leveraging state-of-the-art CNC machinery and equipment, the factory aims to enhance precision, efficiency, and overall productivity across all manufacturing processes. The integration of CNC technology enables the factory to produce highly accurate and complex components, catering to a broad spectrum of industries such as automotive, aerospace, electronics, and more.With its extensive track record in the automotive industry, the Chinese TS16949 factory has gained valuable insights into the demands for precision engineering and stringent quality standards. By combining its TS16949 certification with CNC manufacturing capabilities, the factory now offers an unparalleled level of craftsmanship and adherence to regulatory requirements. Customers can expect exceptional product quality, reduced lead times, and competitive pricing.Furthermore, the factory's decades of experience have established its reputation as a reliable and customer-focused organization. Through this strategic transformation, the factory is poised to enhance its customer-centric approach by offering an expanded range of services. Beyond conventional machining and manufacturing processes, the factory can now provide value-added services such as design optimization, prototyping, and even post-processing treatments like surface finishing or heat treatment, ensuring that customer requirements are met comprehensively.The integration of CNC technologies within the factory's operations also translates into improved production flexibility. CNC machinery offers greater versatility, allowing for the production of various component sizes, materials, and complexities. This adaptability enables the factory to accommodate diverse customer needs, regardless of volume or specific specifications. The ability to handle both small-scale intricate projects and large-scale manufacturing orders positions the factory as a reliable one-stop solution for CNC manufacturing requirements.Another noteworthy advantage of the factory's transformation is the substantial reduction in production time. CNC technology's automation capabilities streamline manufacturing processes, significantly increasing production efficiency. The factory can expedite order fulfillment, shorten lead times, and maintain consistently high production outputs. This enhanced efficiency enables the factory to remain competitive in a rapidly evolving business landscape, ultimately benefiting its clientele.Moreover, the adoption of CNC technologies serves as a catalyst for research and development endeavors within the factory. With an increased focus on precision engineering and cutting-edge manufacturing techniques, the factory's team can now actively engage in continuous innovation, staying ahead of industry trends and customer demands. This commitment to pushing technological boundaries ensures that the factory remains at the forefront of the CNC manufacturing sector, offering solutions that align with the ever-evolving market dynamics.Conclusion:The transformation of a Chinese TS16949-certified factory into a state-of-the-art CNC manufacturing hub marks a pivotal moment for the organization and the industry as a whole. By embracing CNC technologies, the factory showcases its commitment to precision engineering, exceptional customer service, and staying ahead of market demands. The integration of CNC capabilities not only enhances the factory's manufacturing processes but also positions it as a comprehensive solution provider for customers seeking high-quality, precision-engineered components. As the factory continues to leverage this transformation, it is poised to reinforce its status as a major player in the CNC manufacturing industry, further solidifying China's position as a global hub for advanced manufacturing.

Exploring the Outstanding Properties of Aluminum Alloy – A Game-Changer in Several Industries

[Company Name] Launches Innovatively Engineered Aluminum Alloy for High-Performance Applications[City, Date] - [Company Name], a leading innovator in material science and engineering, has unveiled its latest breakthrough in aluminum alloy technology. The company's cutting-edge alloy promises to revolutionize the industry with its superior strength, lightweight properties, and exceptional performance characteristics. This new development is set to have far-reaching implications in various sectors, including aerospace, automotive, construction, and consumer electronics.[Company Name] has been at the forefront of materials research and development for over two decades. With a strong focus on innovation and sustainability, the company has consistently produced groundbreaking solutions that cater to the evolving needs of its clients. This latest aluminum alloy is no exception. Its unique composition and manufacturing process result in a material that surpasses the traditional limitations of aluminum, offering enhanced strength, durability, and corrosion resistance.One of the standout features of this new aluminum alloy is its remarkable strength-to-weight ratio. Engineers and designers can now create structures and products that are both lightweight and exceptionally strong. This characteristic makes it an ideal choice for applications that demand high-performance and reliable materials. Additionally, the alloy's excellent fatigue resistance ensures longevity, making it a cost-effective solution in the long run.The aerospace industry, in particular, stands to benefit greatly from [Company Name]'s groundbreaking innovation. The alloy's superior strength and lightweight properties provide crucial advantages in aircraft construction, where weight reduction is of utmost importance for fuel efficiency and increased payload capacity. It also exhibits exceptional corrosion resistance, ensuring the longevity and safety of critical aircraft components.The automotive industry is another area where the new alloy can make a significant impact. As the demand for electric vehicles continues to rise, lightweight materials are essential to maximize battery efficiency and extend driving range. [Company Name]'s aluminum alloy offers automakers the perfect solution, enabling them to reduce vehicle weight without compromising structural integrity or safety.In the construction sector, this alloy presents exciting possibilities for designers and architects. Its high strength and durability make it an ideal choice for structural components, allowing for more creative and efficient designs. Additionally, the lightweight nature of the alloy simplifies installation processes and reduces construction time and costs.Consumer electronics manufacturers stand to benefit from the alloy's desirable properties as well. From smartphones to laptops and wearables, lightweight materials are increasingly sought after for their portability and aesthetic appeal. [Company Name]'s aluminum alloy provides a durable and visually pleasing solution, accommodating the demand for sleek and slim designs without compromising device performance.Furthermore, the alloy's environmental advantages are of paramount importance in today's world. It boasts a lower carbon footprint compared to traditional materials, thanks to its recyclability and energy-efficient manufacturing process. This aligns with [Company Name]'s commitment to sustainability and ensures that the new alloy meets the growing demands of eco-conscious industries.In conclusion, [Company Name]'s groundbreaking aluminum alloy marks a significant advancement in material science. With its exceptional strength, lightweight properties, and environmental benefits, the alloy has the potential to reshape various industries. Whether it's in aerospace, automotive, construction, or consumer electronics, the applications of this innovative alloy are limitless. [Company Name] continues to drive the boundaries of material technology, cementing its position as a leader in the field.

Aluminum Part Manufacturer Unveils Innovative Product for Enhanced Performance

[Header][Date][Headline]Aluminum Part Revolutionizes Manufacturing Industry[Subtitle]Company [Company Name] Introduces an Innovative Aluminum Part that Enhances Efficiency and Durability[Location] – In a groundbreaking development, [Company Name], a leading manufacturer in the industrial sector, has unveiled a state-of-the-art aluminum part that is set to revolutionize the manufacturing industry. With its unique design and advanced features, this new aluminum component promises to greatly enhance production efficiency, durability, and overall performance for a wide range of applications.[Paragraph 1]Over the years, aluminum has become the preferred material in various industries due to its exceptional qualities, including lightweight properties, high strength-to-weight ratio, and excellent corrosion resistance. Recognizing the immense potential of aluminum, [Company Name] has dedicated significant resources to develop an aluminum part that surpasses existing market standards.[Paragraph 2]The newly developed aluminum component, whose branding will be removed for editorial purposes, is set to disrupt existing manufacturing practices. Engineered with utmost precision and integrity, this aluminum part boasts a number of groundbreaking features that offer unparalleled advantages to the end-user.[Paragraph 3]One of the key highlights of this innovative aluminum part is its superior structural integrity. Through advanced manufacturing techniques and rigorous quality control measures, [Company Name] has achieved a product that ensures remarkable durability and longevity. This means reduced maintenance costs and increased productivity for manufacturers across various sectors.[Paragraph 4]The unique design of the aluminum part also addresses common challenges faced by manufacturers, such as cumbersome installation processes and compatibility issues. With its user-friendly interface and flexible installation options, this aluminum component seamlessly integrates into existing systems, allowing for hassle-free upgrades and greatly minimizing downtime for production facilities.[Paragraph 5]Moreover, the improved efficiency provided by this aluminum part enables manufacturers to enhance their competitive edge. By reducing energy consumption, optimizing production cycles, and streamlining overall operations, companies can achieve significant cost savings while also minimizing their environmental impact. This development underlines [Company Name]'s commitment to sustainable manufacturing practices.[Paragraph 6]In addition to its superior performance, the aluminum part also offers a wide range of customization options to suit the specific needs of different industries. [Company Name] ensures that its clients can tailor the component according to their requirements, whether it be for automotive, aerospace, construction, or any other sector that relies on top-quality aluminum parts.[Paragraph 7][Company Name]'s cutting-edge aluminum part has already garnered significant praise from industry experts. By leveraging its extensive research and development capabilities, combined with its commitment to unparalleled quality standards, the company has succeeded in pushing the boundaries of what aluminum can achieve in the manufacturing sector.[Paragraph 8]The launch of this revolutionary aluminum part highlights [Company Name]'s ongoing dedication to technological innovation, aiming to drive progress and improve the overall performance of the manufacturing industry. With its proven track record and commitment to customer satisfaction, [Company Name] has solidified its position as a trusted name in providing superior aluminum solutions.[Quote]"[Company Name] is proud to introduce this game-changing aluminum part to the market," says [Spokesperson's Name], a representative of the company. "Our team has worked tirelessly to develop a product that exceeds expectations, revolutionizing the way manufacturers operate. This aluminum part will undoubtedly deliver exceptional value to our customers."[Paragraph 9]As the global manufacturing industry continues to evolve, innovations such as [Company Name]'s aluminum part pave the way for enhanced efficiency, durability, and sustainability. With this groundbreaking development, businesses across sectors can confidently embrace the future of manufacturing, knowing they have a reliable and high-performing aluminum component at their disposal.[Closing]For more information on [Company Name] and its groundbreaking aluminum part, please visit [Company Website].

Top Auto Body Parts for Enhancing Your Vehicle's Appearance

Auto Body Part Launches New Product Line, Revolutionizing the Automotive Industry[City Name], [Date] - Auto Body Part, a leading manufacturer and supplier in the automotive industry, announced today the launch of their highly anticipated new product line. This innovative range of auto body parts is set to revolutionize the industry by providing customers with superior quality products that offer exceptional value for money. With a commitment to excellence and customer satisfaction, Auto Body Part is poised to become a game-changer in the market.Auto Body Part has been an established player in the automotive aftermarket for over two decades. Known for their extensive range of automotive body parts and accessories, the company has built a solid reputation for delivering top-notch products that meet the highest industry standards. Their dedication to using cutting-edge manufacturing techniques and sourcing the finest materials has earned them a loyal customer base worldwide.The new product line unveiled by Auto Body Part showcases their commitment to innovation and providing customers with the best possible solutions. By leveraging their industry expertise and keeping up with the latest trends, the company has developed an impressive range of auto body parts that are designed to enhance the performance and aesthetics of any vehicle.One of the highlights of the new product line is the introduction of advanced composite materials. Auto Body Part has invested significant resources in research and development to create composite body panels that offer superior strength, durability, and weight reduction. These lightweight panels not only improve fuel efficiency but also contribute to a higher overall performance of the vehicle. Additionally, their resistance to corrosion and extreme weather conditions ensures longevity and hassle-free maintenance.In addition to composite body panels, Auto Body Part has also expanded their offerings to include a wide range of other auto body parts. From fenders and bumpers to grilles and headlights, customers can now find everything they need to repair and customize their vehicles under one roof. The company's commitment to diversity and catering to the needs of their customers is clearly reflected in this expanded product line.To ensure seamless compatibility and ease of installation, Auto Body Part has developed a comprehensive range of products that are specifically designed for different makes and models of vehicles. This attention to detail and commitment to precision is what sets Auto Body Part apart from their competitors. With their user-friendly online catalog and knowledgeable customer service team, customers can find the perfect fit for their vehicle without any hassle."We are extremely excited to introduce our new product line to the market. At Auto Body Part, we strive to exceed customer expectations and set new benchmarks in the industry," said [Company Spokesperson]. "Our team has worked tirelessly to develop these high-quality auto body parts, and we are confident that our customers will appreciate the performance, durability, and aesthetic appeal of our products."Auto Body Part understands that customer satisfaction is crucial for their success, which is why they stand behind every product they sell with a comprehensive warranty. This not only gives customers peace of mind but also highlights the company's commitment to standing behind the quality of their products.With the launch of their new product line, Auto Body Part is all set to disrupt the automotive industry by offering customers innovative solutions that combine performance, aesthetics, and durability. As the company continues to grow and evolve, it remains committed to providing the highest level of service and value to its customers.

Maximizing Efficiency and Precision: Exploring the Benefits of Metal Stamping Parts

Metal Stamping Part: Revolutionizing the Manufacturing IndustryIn the ever-evolving world of manufacturing, metal stamping has emerged as a game-changer for the industry. Offering precision, efficiency, and cost-effectiveness, metal stamping has revolutionized the production of various components, allowing companies to meet the demands of a rapidly changing market.Metal stamping involves the process of shaping and forming metal sheets into desired shapes and sizes. This manufacturing technique utilizes a highly specialized machinery known as a stamping press, which applies pressure to the metal sheet, thereby imprinting the desired design. This process has been widely adopted by numerous industries, including automotive, aerospace, electronics, and many more.One company at the forefront of the metal stamping revolution is {}. With decades of experience in the industry, they have established themselves as a leading manufacturer of metal stamping parts. Committed to delivering excellence and innovation, they have captured the attention of both domestic and international clients.Using state-of-the-art technology and machinery, {} is able to produce metal stamping parts with unparalleled precision and accuracy. By leveraging the expertise of their highly skilled engineers and technicians, they have successfully developed a wide range of components that cater to the diverse needs of their customers.The advantages of metal stamping are manifold. Firstly, this manufacturing technique allows for the production of parts with high dimensional accuracy, ensuring a seamless fit in the final product. This precision is crucial in industries such as automotive and aerospace, where even the slightest deviation can lead to catastrophic consequences.Secondly, metal stamping offers great efficiency in terms of production speed. With the ability to produce thousands of parts per hour, manufacturers can meet large-scale demands without compromising on quality. This increased efficiency has significantly reduced production times and costs, giving companies a competitive edge in today's fast-paced market.Furthermore, metal stamping enables the production of complex and intricate designs that would be otherwise unattainable through traditional manufacturing methods. This versatility allows designers and engineers to explore new possibilities and push the boundaries of innovation.Another notable advantage of metal stamping is its cost-effectiveness. By utilizing high-speed stamping presses and automated production lines, manufacturers can achieve economies of scale, thereby reducing production costs. This cost reduction is crucial for businesses aiming to stay competitive in an increasingly price-sensitive market.As society becomes more environmentally conscious, metal stamping also offers environmentally friendly benefits. The high level of efficiency and precision in metal stamping minimizes material waste, conserving resources and reducing the carbon footprint of manufacturing processes. Additionally, the use of recyclable materials further contributes to a sustainable production cycle.Looking towards the future, metal stamping is poised to undergo further advancements. With ongoing research and development efforts, manufacturers are continually improving the capabilities of their stamping presses, resulting in even higher levels of precision, efficiency, and versatility.In conclusion, metal stamping has revolutionized the manufacturing industry by providing precision, efficiency, and cost-effectiveness. Companies like {} have played a pivotal role in driving this revolution, offering high-quality metal stamping parts to a wide range of industries. As the industry continues to evolve, metal stamping will undoubtedly play a vital role in shaping the future of manufacturing.

PVC Leather Steering Wheel Cover: Enhance Your Driving Experience with this Luxury Accessory

Title: PVC Leather Steering Wheel Covers: An Innovative Addition to Driver ComfortIntroduction:In today's automotive market, manufacturers are continually striving to enhance the driving experience through innovative and ergonomic designs. One such product that has gained significant popularity among drivers is the PVC leather steering wheel cover. This accessory not only adds a touch of style to the interior of the vehicle but also provides increased comfort and grip. In this article, we will explore the features and benefits of the PVC leather steering wheel cover, and how it has become a must-have item for modern drivers.I. The Features of PVC Leather Steering Wheel CoversPVC leather steering wheel covers are designed to provide multiple advantages to drivers. Some of the key features include:1. Comfortable Grip: The PVC leather material offers a soft and comfortable grip, ensuring a pleasant driving experience even during long journeys. The cushioning effect of the cover reduces hand fatigue and absorbs vibrations, leading to increased control and precision.2. Enhanced Safety: The textured surface of the PVC leather cover provides a non-slip grip, reducing the risk of slippage during sudden maneuvers or emergency situations. This added safety feature contributes to overall driver confidence and control.3. Protection from Wear and Tear: Steering wheels are subjected to constant use and can become worn or scratched over time. PVC leather covers act as a protective barrier, preventing damage to the original steering wheel surface and maintaining its longevity.4. Customization and Style: Available in a variety of colors and designs, PVC leather steering wheel covers allow drivers to personalize their car interiors according to their preferences. This accessory provides a stylish upgrade to the existing steering wheel, giving the vehicle a modern and visually appealing look.II. Benefits of PVC Leather Steering Wheel Covers1. Easy Installation: PVC leather steering wheel covers are designed for hassle-free installation, making it convenient for drivers to enhance their driving experience. The simple and quick installation process allows for immediate usage and does not require any special tools or expertise.2. Cost-Effective Solution: Compared to replacing the steering wheel entirely, PVC leather covers offer a cost-effective alternative that produces similar results. With their affordable price range, drivers can enjoy the benefits of a comfortable and stylish steering wheel without breaking the bank.3. Easy Maintenance: PVC leather is known for its durability and ease of maintenance. Steering wheel covers made from this material can be easily cleaned using a damp cloth or mild cleaning solution, ensuring they remain in excellent condition for an extended period.III. ConclusionThe PVC leather steering wheel covers have revolutionized the way drivers interact with their vehicles. With their ergonomic design, enhanced grip, and visual appeal, these covers have become an indispensable accessory for modern drivers. Their ability to provide comfort, safety, and protection, at an affordable price, makes them a popular choice among car enthusiasts worldwide. So, if you are looking to upgrade your driving experience and personalize your car's interior, consider adding a PVC leather steering wheel cover for enhanced comfort and style.

Efficient Lighting Solutions Stepping Up: Find out What the Industry is Buzzing About!

[News Title]: Revolutionizing Lighting Industry: New Innovations by Leading Company[News Content]:In recent years, the lighting industry has witnessed a remarkable evolution, driven by advancements in technology and growing consumer demand for energy-efficient and sustainable lighting solutions. One company, which has emerged as a frontrunner in this domain, is leading the charge with their groundbreaking innovations. This article will shed light on the various facets of its operations and explore the impact they are making on the lighting industry.Founded on the principles of innovation and sustainability, [Company Name] has revolutionized the lighting industry with its cutting-edge technologies and forward-thinking approach. Committed to designing and manufacturing products that enhance efficiency, reduce energy consumption, and minimize environmental impact, [Company Name] has become a leading name in this rapidly growing sector.One of the key areas where [Company Name] distinguishes itself is in the field of LED lighting. By harnessing the power of Light Emitting Diodes (LEDs), they have succeeded in developing lighting solutions that offer superior performance while being remarkably energy-efficient. LED lighting allows for longer lifespan, reduced maintenance costs, and significant energy savings when compared to traditional lighting sources such as incandescent or fluorescent bulbs. By actively promoting the adoption of LEDs, [Company Name] has paved the way for a greener and more sustainable lighting future.In addition to LED lighting, [Company Name] is also actively involved in research and development to explore other cutting-edge technologies. For instance, they are investing in the development of smart lighting systems, which enable seamless integration with automation and control systems. Through the utilization of sensors, connectivity, and advanced algorithms, these intelligent lighting systems can adapt to the needs of the users in real-time, optimizing energy consumption and creating comfortable environments. Such innovations are not only transforming the way we illuminate our surroundings but also promoting energy conservation on a global scale.Moreover, [Company Name] is committed to incorporating sustainable practices across its entire supply chain. From sourcing raw materials to manufacturing processes and product packaging, they adhere to stringent environmental standards. By focusing on recyclability, reducing waste, and minimizing the carbon footprint, [Company Name] ensures that their products contribute to a greener future while also meeting the evolving expectations of environmentally conscious consumers.Another aspect that sets [Company Name] apart is their commitment to customer satisfaction. Their comprehensive after-sales support and dedicated customer service ensure that the end-users can enjoy a hassle-free experience. With a strong emphasis on product quality, they have gained the trust of customers worldwide. Their wide range of lighting products caters to various sectors, including residential, commercial, and industrial applications, making them a versatile lighting solution provider.Furthermore, [Company Name] understands the importance of collaborations and partnerships in building a sustainable lighting ecosystem. They actively collaborate with architects, designers, and other industry stakeholders to explore new possibilities and integrate lighting seamlessly into various settings. By fostering such partnerships, they facilitate the exchange of ideas, which further fuels innovation in the field of lighting.Looking ahead, [Company Name] continues to push the boundaries of what is possible in the lighting industry. By investing in research and development, embracing sustainable practices, and fostering collaborations, they are well-positioned to shape the future of lighting. As society increasingly recognizes the importance of energy-efficient and sustainable lighting solutions, [Company Name] stands ready to lead the way, illuminating not only the spaces we inhabit but also a brighter, greener planet.[Word Count: 680]

Benefits and Applications of High-Quality Aluminum Die Cast Parts from China

China Aluminum Die Cast, a leading manufacturer in the casting industry, has been consistently delivering high-quality die-casting solutions to its global clientele. With an aim to provide innovative and reliable products, the company has become a trusted partner for various industries, including automotive, electronics, and aerospace.Established in the early 1990s, China Aluminum Die Cast has evolved to become one of the most influential players in the market. The company's success can be attributed to its advanced manufacturing facilities, cutting-edge technology, and a highly skilled workforce. With an unwavering commitment to quality and customer satisfaction, the company has managed to carve a niche for itself in the highly competitive die-casting industry.China Aluminum Die Cast specializes in the production of high-precision aluminum die-casting components. Utilizing state-of-the-art equipment and advanced manufacturing processes, the company ensures that each and every product meets the highest quality standards. From design and prototyping to finishing and assembly, every step in the production process is meticulously supervised to ensure optimal performance and durability.The company's capabilities extend to various industries, including automotive. With the growing demand for lightweight and fuel-efficient vehicles, China Aluminum Die Cast has successfully developed innovative solutions that meet the industry's stringent requirements. By utilizing aluminum and other lightweight materials, the company's die-casting components contribute to reducing the overall weight of vehicles, resulting in improved fuel efficiency and enhanced performance.In addition to the automotive sector, China Aluminum Die Cast also serves the electronics industry. With the constant evolution of consumer electronics, there is a rising need for smaller, lighter, and more durable components. The company's expertise in high-precision die-casting allows it to produce intricate parts that meet the specific demands of the electronics industry.Furthermore, China Aluminum Die Cast has diversified its offerings to cater to the aerospace industry. The stringent standards and regulations imposed in this sector demand the highest levels of quality and precision. By leveraging its advanced manufacturing processes and stringent quality control measures, the company has successfully become a trusted supplier of critical aerospace components.What sets China Aluminum Die Cast apart from its competitors is its commitment to research and development. The company consistently invests in technological advancements to improve its production capabilities and offer innovative solutions to its customers. By partnering with renowned research institutions and industry experts, China Aluminum Die Cast stays at the forefront of technological advancements, ensuring that its products remain cutting-edge and competitive.Moreover, the company places great emphasis on sustainability and environmental responsibility. Recognizing the impact of manufacturing processes on the environment, China Aluminum Die Cast has implemented various eco-friendly practices. From reducing energy consumption to implementing waste management strategies, the company strives to minimize its carbon footprint and contribute to a greener future.As China Aluminum Die Cast continues to grow and expand its global footprint, it is committed to upholding its core values of quality, innovation, and customer satisfaction. By offering reliable and high-quality die-casting solutions, the company aims to forge long-lasting partnerships with its clients and drive industry advancements.In conclusion, China Aluminum Die Cast has emerged as a significant player in the die-casting industry, renowned for its commitment to quality, innovation, and customer satisfaction. With its advanced manufacturing facilities, cutting-edge technology, and skilled workforce, the company continues to deliver exceptional die-casting solutions to various industries. By staying at the forefront of technological advancements and prioritizing sustainability, China Aluminum Die Cast is poised to lead the way in the global casting market.